Top Features of Drag Racing Axles for Extreme Performance

Key Highlights

- Drag racing axles, such as those from Strange Engineering and Mark Williams Enterprises, are specifically designed to withstand extreme torque and high-performance demands.

- Steel alloys featuring molybdenum and manganese ensure tensile strength and durability, supporting elite-level drag racing applications.

- Advanced CNC manufacturing achieves precise designs, including axle flanges and bearing shoulders for optimised fit and strength.

- Diverse spline counts, like 28, 31, 33, and 35, impact torque handling, enabling racers to choose axles for specific applications.

- Compatibility features allow easy installation with Ford, GM, Pontiac, and Buick rear ends, ensuring user convenience and performance adaptability.

Transitioning into the technical foundation of these axles, let’s explore their superior engineering design and material advantages.

Introduction

Drag racing axles are key parts for any car made for high-speed runs. These axles are very strong because they need to last through the tough work on the track. Race axles are not the same as what you get in a regular car. They are made to be tougher and to keep the rear end strong when you need the best performance. Strange Pro Race Axles and other brands in racing give drivers better options by making lighter axles that still have high tensile strength. The axles work well with a lot of torque, which you see in drag racing. The right axle, like the strange pro race axles, can decide who wins or loses a race.

Let's look at what the design team does to help these axles give better performance for your racing car.

Engineering Excellence in Drag Racing Axles

Industry leaders like Strange Engineering and Mark Williams Enterprises set a high standard for drag racing axles, utilizing advanced processes and premium materials for maximum strength. Strange Pro Race Axles, crafted from aerospace-grade steel, can withstand up to 240,000 psi of tensile strength while maintaining essential flexibility for top-level racing.

They also offer custom solutions, including 35-spline spools and lighter axles tailored to specific power needs. Drag racing drivers trust these brands—including Moser Engineering—for their unique designs, quality materials, and customizable options.

Next, let’s explore the standout materials that enhance these axles.

Advanced Material Selection for Maximum Strength

Top race axles for drag racing are crafted from durable steel, particularly molybdenum steel, renowned for its high strength and longevity. Originally used in military aircraft landing gear, this steel offers exceptional tensile strength and resilience. Combined with manganese, it provides both strength and flexibility, crucial for withstanding significant torque without breaking.

Strange Pro Race products utilize special machining processes to transform this metal mix into high-performance race axles. The steel undergoes treatment that enhances hardness, achieving up to 240,000 psi in tensile strength—far superior to standard steel axles. This process allows the axle to distribute loads effectively while bending slightly under the intense demands of drag racing.

These advanced materials enable race axles to endure quarter-mile times under seven seconds, even in vehicles over 3,500 pounds, demonstrating their reliability. Brands like Hy-Tuf have set industry standards by using robust materials and precise CNC manufacturing processes that enhance both strength and detail.

Precision CNC Manufacturing Processes

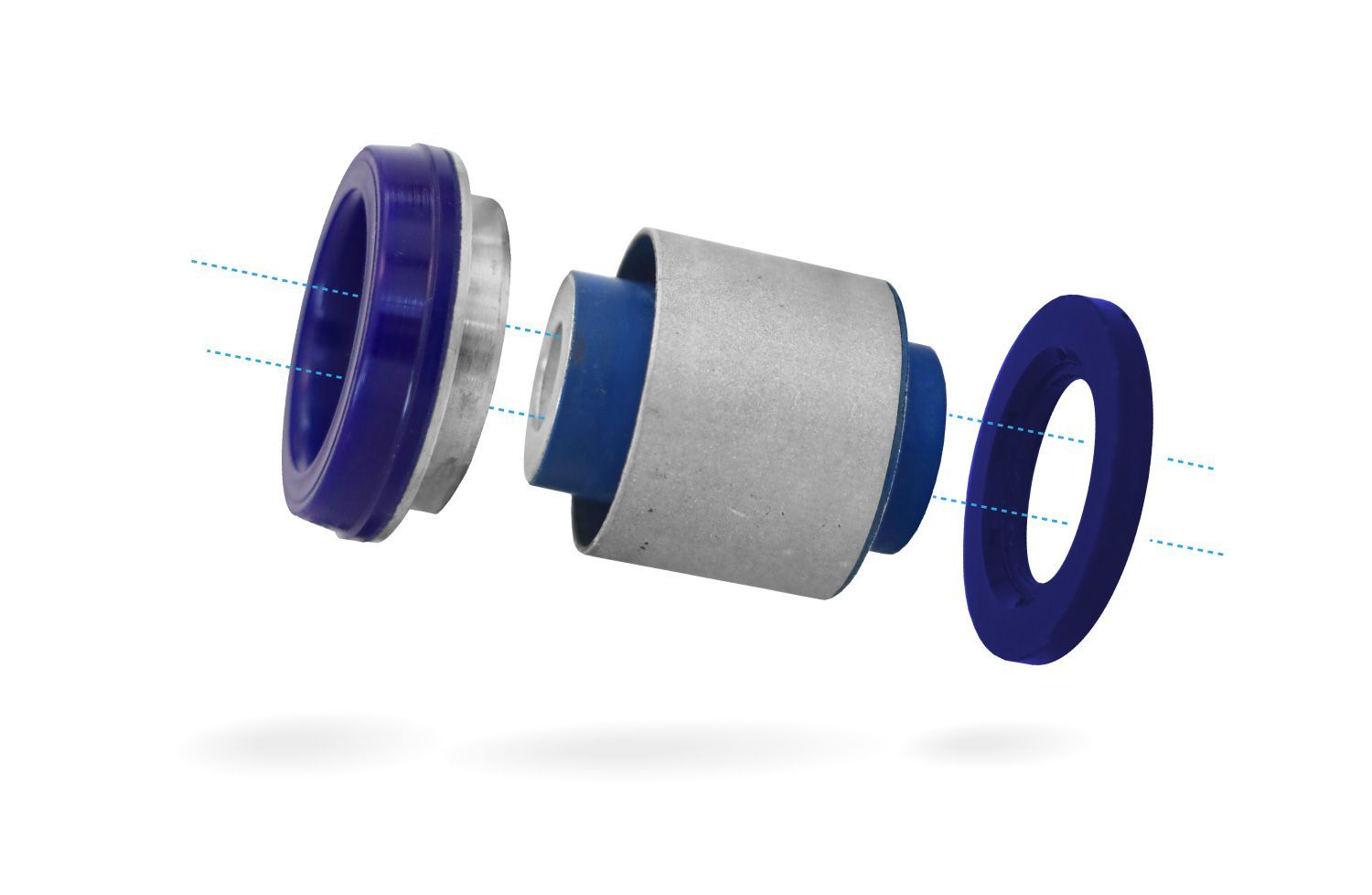

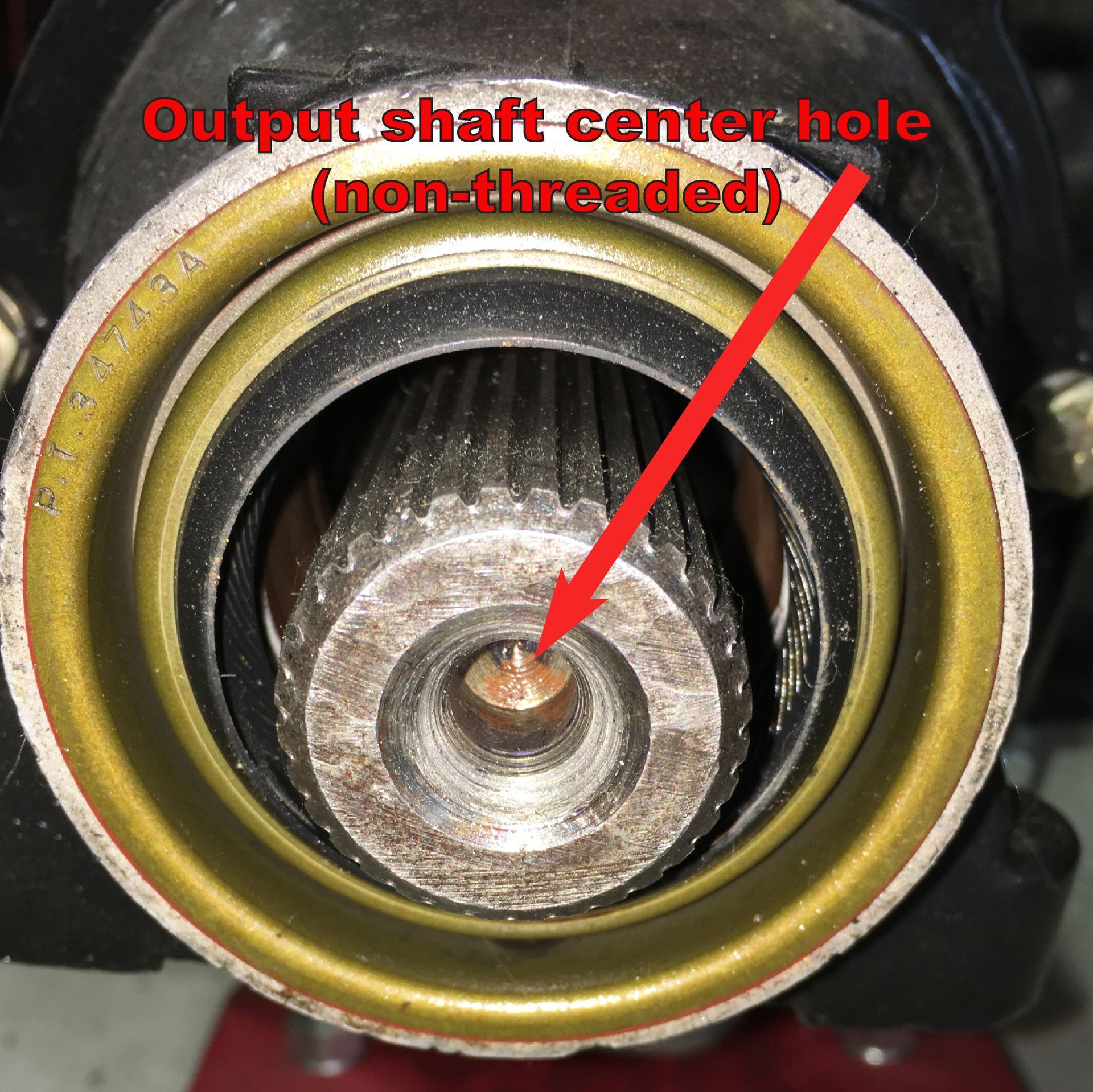

CNC manufacturing is crucial for drag racing axles, ensuring precision in every component from the shaft to the axle flange. The axle shaft begins as raw alloy, shaped to endure high torque and heavy loads. A gun-drilling process removes excess weight while maintaining strength, and strategically placed holes in the axle flange enhance flexibility.

CNC machine centers drill and tap designs, ensuring each setup is tailored for its specific use. The shoulder around the axle bearing is engineered to minimize wheel bend and reduce friction, enhancing alignment and torque transfer for durability in racing.

Carefully machined splines utilize involute designs for optimal fit and strength, allowing drag racers seamless gear engagement and maximum power on race day. Next, we will explore how varying spline counts can further improve axle performance.

Spline Counts and Their Role in Performance

Spline axles are crucial in drag racing, transferring torque from the differential to the wheels for optimal traction. The spline count—28, 31, 33, or 35—affects axle durability and torque capacity. Higher spline counts increase diameter and strength, offering racers more customization.

Serious competitors often prefer 35-spline axles or higher for better torque handling. While lower-spline axles are more affordable, they may not withstand high-power demands in drag racing.

Evaluating different spline counts reveals their specific advantages, catering to various racing needs.

Comparing 28, 31, 33, and 35 Spline Axles

Spline counts significantly impact drag racing performance. While 28-spline axles are traditional, they may not handle the extreme torque of elite racing. In contrast, 31-spline options offer a balance of strength and durability. For maximum resilience, 33 and 35-spline axles excel with superior tensile strength and higher RPM capabilities. Higher spline counts enhance axle integrity during intense launches, improving horsepower transfer and reducing axle failure risk—crucial for precision-driven racers. Understanding these design nuances allows racers to make informed choices to optimize vehicle performance on the track.

How Spline Count Impacts Torque Handling

The number of splines on an axle is crucial for its torque capacity. More splines create thicker sections between grooves, enhancing strength. Axles with 35 or more splines can handle greater psi and prevent breakage by allowing some stretch under shock. Solid axles with many splines flex like torsion bars instead of breaking.

A higher spline count also ensures smoother power transfer to the rear end, improving stability at high speeds. For heavy loads up to 12,000 lb-ft of torque, a robust 40-spline axle made from chrome moly is ideal.

In contrast, standard 28-spline axles often fail in demanding racing conditions due to inadequate strength for high torque outputs. Racers typically seek higher spline counts for optimal performance, especially in drag racing where power is critical.

Installation and Compatibility Features

Drag racing axles offer versatile installation options for various rear ends, including Ford, GM, Pontiac, and Buick. With appropriately sized stud holes and C-clip eliminator kits, setup is streamlined. These axles feature high-quality bearings and retainer plates for a secure fit on any car, designed to withstand the rigors of tough racing events. Custom setups are available to suit individual racing styles. Strange Engineering provides kits compatible with lightweight steel spools for added versatility and easy installation, simplifying rear end upgrades. C-clip eliminator kits enhance safety in competitive racing.

C-Clip Eliminator Kits and Retainer Plates

C-clip eliminator kits are essential for drag racing, preventing axle breakage during intense runs. These kits replace stock parts, keeping the axle aligned for enhanced safety. Adding retainer plates further strengthens the axle, crucial for tough races.

Benefits of C-clip eliminators include:

- Reduced risk of axle or wheel detachment at high speeds.

- Improved fit with lightweight Dana spools and brackets.

- Stabilization of the wheel housing.

- Enhanced axle bearing durability during races.

- Simplified installation with GM and Ford setups.

Retainer plates, made from robust materials, provide additional support when used with Strange Pro Race packages, ensuring professional racing cars remain safe and durable.

Special axle stud kits are also available for precise fits.

Axle Stud Kits and Custom Fitment Options

Axle stud kits securely lock wheels in place, with options for ½-inch or 5/8-inch studs to ensure precise fitment and prevent misalignment during races. Strange Engineering's chrome moly full float setup allows for rear-end adjustments. Compatible with various cars, including Ford, GM, and Buick, these kits optimize caliper placement for effective braking and stability. Professional racers favor lightweight yet durable axle and stud configurations. The materials used increase strength; chrome moly enhances drag race performance. Custom fitments are available for lightweight steel spools and robust racing bearings. Overall, these features provide a reliable setup, ensuring strong and stable performance at the track when paired with vehicle-specific components.

Conclusion

To sum up, drag racing axles are made with great care to stand up to tough use. They are built from strong materials. The cutting of each axle uses special CNC machines, which help make the axles last longer and handle more power. Knowing about spline counts and what they do can really make a difference in the way your vehicle moves. You can get axles that fit what you need for racing. Also, things like C-Clip eliminator kits make installation easy. It is now simple to upgrade your setup. If you want the best out of your drag racing, choose axles that give you both strength and trust that they will work every time. Check out what we have to offer for spline, drag racing, and racing axles. Take your racing game up a notch today!

Frequently Asked Questions

What makes a drag racing axle different from a standard axle?

Drag racing axles are not the same as standard axles. They be stronger and can handle up to 240,000 psi. This is because the axles be made with a special steel alloy. The steel is made just for racing. The axle bearings in these axles also be tough. You can find these with extra strong bearing support. Some have gun-drilled hollow shafts, so the axle be stronger but lighter. All of these features make them good for hard drag racing and help the car last longer on the track.

How do I choose the right spline count for my build?

Choosing the right spline count depends on what you need for your build. If you are working with torque axles and want it for drag racing or ultimate drag setups, you should go with 35 or more splines. These can handle higher loads and will work best for racing. If your car is lighter or it will be used for street-performance only, then a smaller spline count like 28 or 31 is good. Each build has its own specific applications, so always think about what you need before you pick a spline.

Are gun-drilled axles safe for street use?

Gun-drilled axles are best for pro racing. They are not the right choice for using on the street. Solid axles can take a lot of pressure. So, they are good if you need something tough for hard jobs. If you want something safer that lasts a long time, chrome moly full float setups are what many people use. These work well for non-racing cars and trucks. This means you get a strong axle without having to race.

Can I upgrade my current axles without replacing the whole rear end?

Yes, you can upgrade the rear end without having to change out the whole thing. Modern axle designs let you make changes like getting a custom fit, improving the axle flange, and upgrading the axle bearing shoulder. This lets you fit the new parts into your setup with no trouble.

What maintenance is required for extreme performance axles?

Taking care of race axles means you need to check and service axle bearings often. You also need to be sure the axle flange stays strong. Having the right level of tensile strength is important for axle safety. Look at the studs and splines to see if there is any wear on them. Using retainer plates, as well as good racing lubricants, will help the axle work well and last longer.

dana moser bearings spool ford shaft gm caliper bracket

https://www.youtube.com/channel/UCheMfttsl3BZV1dyokhrpSA

https://www.youtube.com/channel/UCsYD-L7YWy-xUUr-WBkGTmg

https://www.youtube.com/user/MoserEngineering/videos