Slide title

Write your caption here

Button

Slide title

Write your caption here

Button

Slide title

Write your caption here

Button

Slide title

Write your caption here

Button

Slide title

Write your caption here

Button

Slide title

Write your caption here

Button

Slide title

Write your caption here

Button

Slide title

Write your caption here

Button

Slide title

Write your caption here

Button

Slide title

Write your caption here

Button

Slide title

Write your caption here

Button

Slide title

Write your caption here

Button

Slide title

Write your caption here

Button

Slide title

Write your caption here

Button

Slide title

Write your caption here

Button

Welcome to the ultimate guide on Jeep Grand Cherokee axles! Whether you're a seasoned off-roader or a new owner, understanding your vehicle's axles is key to its performance and reliability. The axles are the final link in your drivetrain, responsible for turning engine power into forward motion. This guide will provide general info on everything from identifying your stock axles to exploring heavy-duty upgrades, ensuring your Grand Cherokee is ready for any adventure you have in mind.

The axles on your Grand Cherokee are crucial components that support the vehicle's weight and transfer power to the wheels. You have a front axle and a rear axle, each containing an axle shaft that rotates to spin the tires. These components are housed within sturdy axle tubes designed to withstand the stress of daily driving and off-road excursions.

Understanding the type and condition of your axles is vital for maintenance and potential upgrades. Different generations of the Grand Cherokee came with various axle models, each with its own strengths and weaknesses. Let's look closer at the basic parts of an axle assembly.

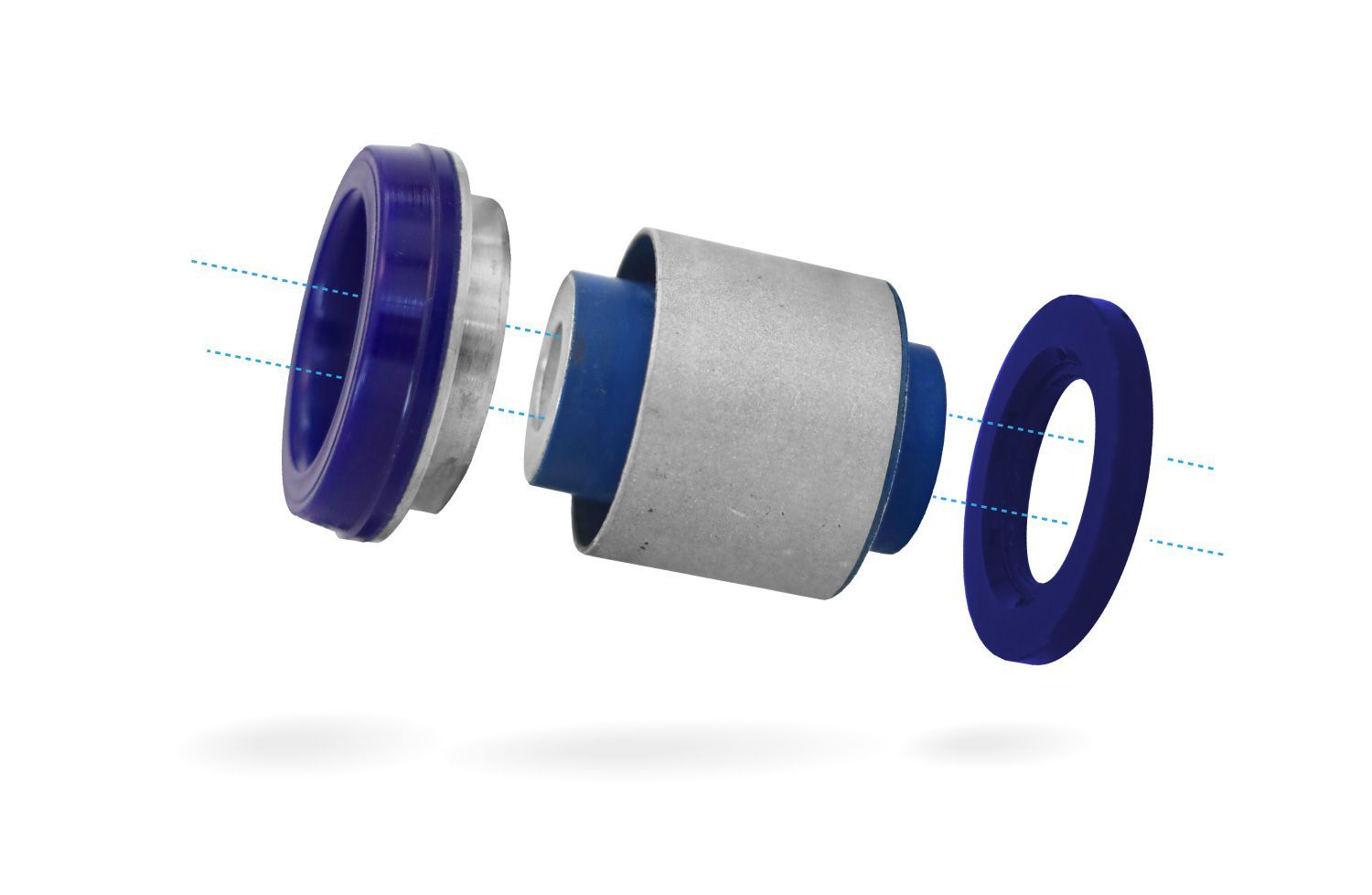

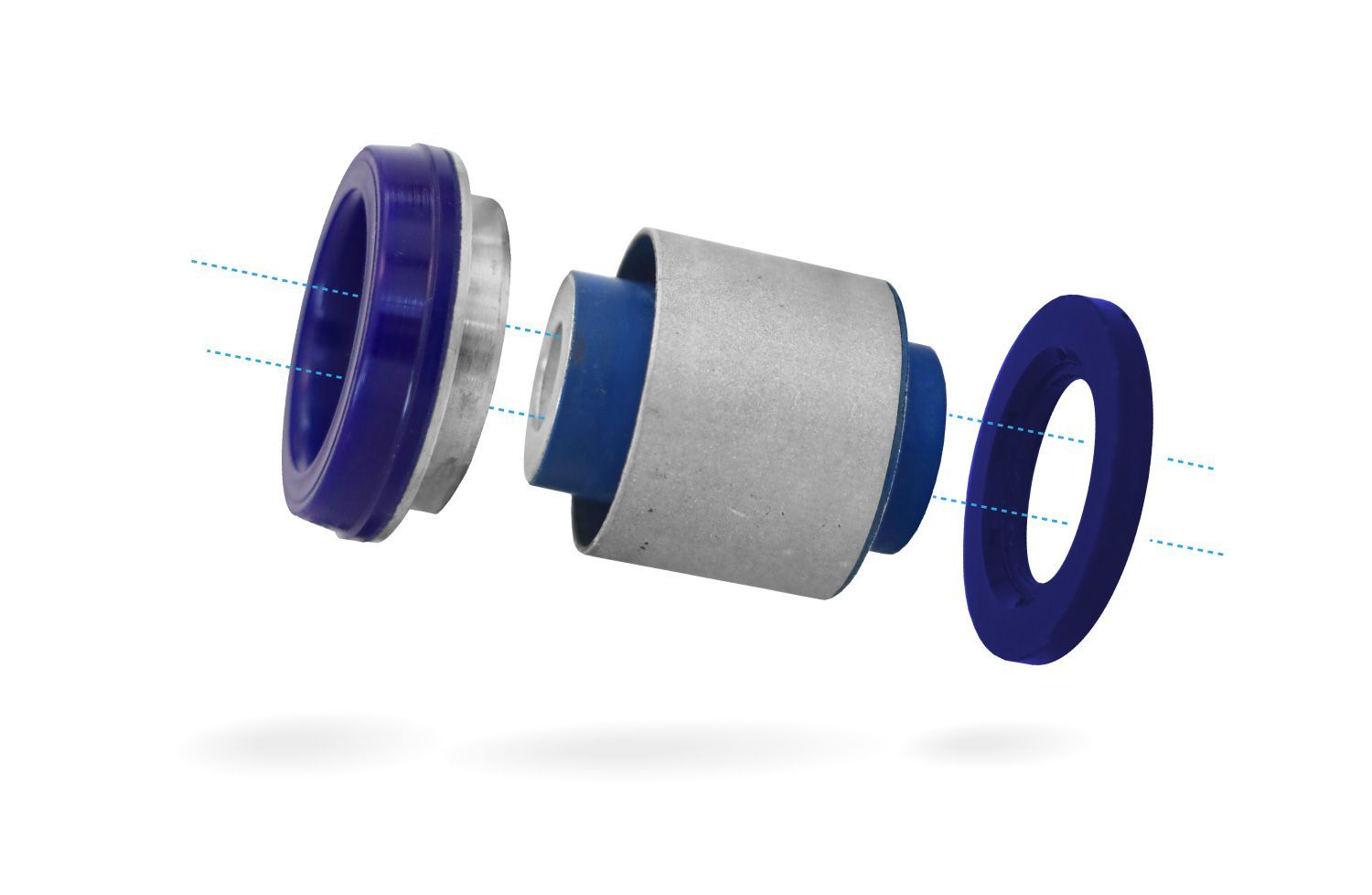

An axle assembly is more than just a metal bar. It consists of several key parts working together. The main housing contains the differential, which allows your wheels to spin at different speeds when turning. You can often identify an axle by the shape of its diff cover. Extending from the housing are the axle tubes, which protect the axle shafts that connect the differential to the wheels.

These spline shafts are what truly transmit power. The number of splines and the material of the shaft determine its strength, which is critical in high-stress situations like racing applications or extreme off-roading. For many stock axles, the axle shaft itself can be the main weak point.

Over its long production run, the Jeep Grand Cherokee has been equipped with several different types of axles. Much like the classic Cherokee XJ, early Grand Cherokee models utilized a mix of Dana and Chrysler corporate axles. The specific combination of front and rear axles often depended on the trim level, engine, and optional packages selected by the original owner.

For instance, the Jeep Grand Cherokee WJ and earlier ZJ models commonly featured a Dana 30 front axle. The rear axle could be a Dana 35, a slightly stronger Chrysler 8.25, or the highly desirable Dana 44. These variations in spline axles and axle tubes make proper identification essential before planning any upgrades.

The Dana axle series is legendary in the off-road world, and several models found their way under the Grand Cherokee. The Dana 35 is often considered the weakest of the bunch and is not recommended for serious off-roading with large tires. It was common on models with ABS and often had the smallest brakes.

Some owners look to swap in even stronger axles, like a JK Dana 44 or an HD axle from another vehicle like an Isuzu Rodeo or Ford Explorer, though this requires significant fabrication. For those seeking the most HD axles without custom work, aftermarket companies offer bolt-in solutions.

As the Jeep Grand Cherokee evolved, so did its axles. The first generation (Grand Cherokee ZJ) and second generation (Jeep Grand Cherokee WJ) primarily used solid front and rear axles from Dana and Chrysler. You could often find a Dana 44 rear axle under V8 models, which remains a very good upgrade for other Jeeps.

Starting with the Grand Cherokee WK, Jeep began transitioning to an independent front suspension (IFS) for improved on-road handling. This marked a significant departure from the solid front axles of the past. These changes continued through subsequent generations, with axles being refined for strength, weight, and efficiency.

The fourth-generation Grand Cherokee WK (2011-2022) continued with an independent front suspension and introduced more refined rear axle assemblies. The focus for these models was to improve on-road comfort and achieve better fuel economy. The axles were designed to be lighter without sacrificing the vehicle's legendary capability.

Despite these improvements, the factory half-shafts in the front can be a main weak point when subjected to the stress of large tires and aggressive off-roading. The axle tubes on the rear solid axle are generally strong, but hardcore enthusiasts often look to upgrade the internals for added peace of mind.

The fifth and latest generation, the Grand Cherokee WL, introduces the most advanced drivetrains yet, including those for the three-row Grand Cherokee L. These vehicles are engineered for a premium ride, but Jeep has not forgotten its off-road heritage. The Trailhawk models, in particular, come with sophisticated traction control systems and robust axle components designed to handle tough conditions.

The integration of features like the electronic parking brake directly into the rear axle assembly adds complexity. However, the underlying principles remain the same: delivering power reliably to the ground, whether you're on the highway or a rocky path.

So, how do you figure out which axle is under your Grand Cherokee? Proper axle identification is the first step before ordering parts or planning an upgrade. The type of axle can vary based on your vehicle's model year, engine, and optional packages, so you can't always assume it's the same as another Jeep that looks similar.

Luckily, there are several ways to identify your axle. You can look for specific tags and markings, check your vehicle's documentation, or use visual cues. The following sections will walk you through each method to help you confidently determine what you're working with.

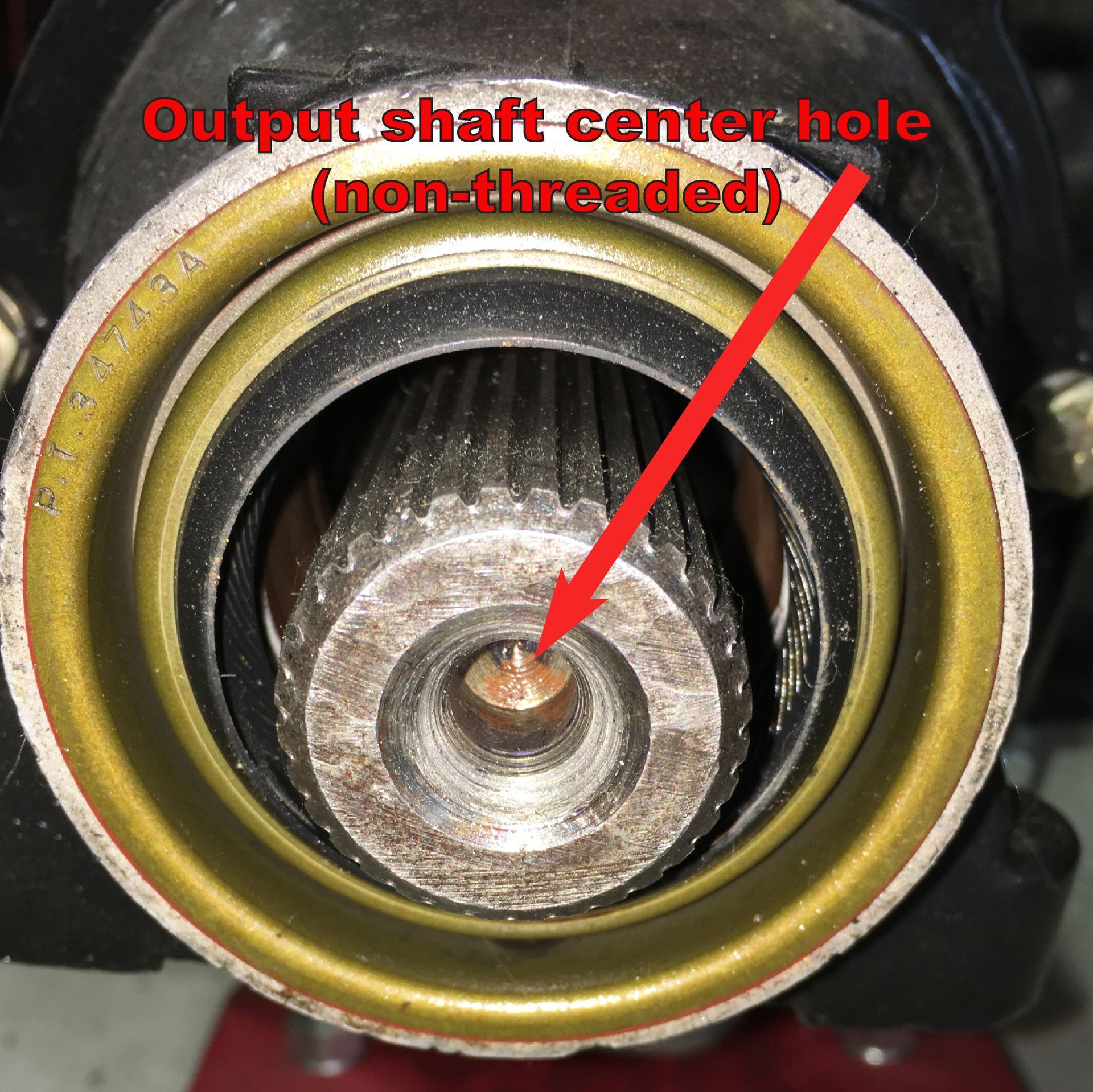

One of the most reliable methods for axle identification is to find the metal tag attached to the differential cover. This tag contains crucial information about your axle, including the gear ratio and model number. It's usually held on by one of the diff cover bolts.

On your front axle or rear axle, look for a small, stamped metal tag. It might be covered in dirt or rust, so you may need a wire brush and some cleaning spray to make it readable. Don't scrub too hard, as you don't want to erase the stamped numbers.

Understanding Dana model markings is essential for anyone delving into axle specifications and performance upgrades. Each Dana axle is labeled with unique identifiers that reveal critical details about size, type, and load capacity. For instance, common markings such as 30, 35, or 44 indicate the axle's series, reflecting their strength and intended applications, including options for both the Jeep Grand Cherokee and its counterparts like the Jeep Wrangler.

Recognizing these markings can significantly impact your decisions, especially regarding aftermarket support and modifications. Knowing whether you have a stout axle for extreme trail use or a lighter setup for better fuel economy allows owners to tailor their vehicles for both on-road comfort and off-road capability. Understanding these codes ensures you choose the right gears and components, optimizing performance for your specific needs.

A Vehicle Identification Number (VIN) serves as a unique identifier for your Jeep Grand Cherokee, critical for obtaining detailed axle information. This alphanumeric code can be found on the dashboard near the windshield or on the driver's side door frame. Once in hand, refer to the build sheet, which provides comprehensive specifications, including axle type and housing details. This resource is invaluable for understanding the specific configurations of your vehicle, ensuring compatibility when considering upgrades or replacements.

Build sheets often reveal critical insights into your Jeep's durability, including spline shafts and axle ratios tailored for various driving conditions. Analyzing these documents helps identify the strengths and weaknesses of your current axle setup, paving the way for informed modifications that enhance performance, whether for daily driving or extreme off-road adventures.

If you can't find a tag or get a build sheet, you can still perform an axle identification with a quick visual inspection. Get under your Jeep (safely, with the vehicle properly supported) and take a look at the differential. The shape of the diff cover is the most telling feature.

As mentioned before, Dana and Chrysler axles have distinct cover shapes. A Chrysler 8.25", for instance, has a flat bottom edge on the housing, unlike the completely rounded Dana 35. The number of bolts holding the cover on is also a key identifier.

Like any mechanical part, your axle can wear out over time. Recognizing the warning signs of a failing axle is crucial to preventing a catastrophic failure that could leave you stranded or cause an accident. Problems can range from worn-out bearings to more serious pinion failures.

The rear axle, in particular, bears a lot of stress, and its internal gears can be a main weak point, especially on older model year vehicles or those with high mileage. Paying attention to new sounds, vibrations, or leaks can help you catch a problem early. Let’s explore some specific signs to watch out for.

One of the first signs of axle trouble is unusual noise. If you hear a whining or howling sound coming from the rear axle that changes pitch with speed, it often points to a worn-out pinion bearing or a bad gear setup. A rumbling or grinding sound, especially when turning, could indicate failing wheel bearings or a problem inside the differential.

Vibrations are another major red flag. If you feel a new vibration that seems to be coming from the driveline, it could be caused by a bent axle shaft or a failing U-joint. These issues are often more noticeable under acceleration or when the drivetrain is under extreme pressure.

Don't ignore these auditory and sensory warnings. A noisy axle is an unhappy axle. The main weak point of any axle assembly is often its smallest moving parts, like bearings, which will protest loudly when they start to fail.

Your axles are filled with a thick gear oil to lubricate the differential and bearings. If you see dark, oily fluid leaking from the ends of the rear axle or from the differential cover, you have a problem. This is a clear sign that your axle seals have failed.

Leaking fluids can come from a few places. A leak near the wheel often means the outer axle shaft seal is bad. If the leak is coming from the front of the differential where the driveshaft connects, it's a pinion seal failure. A leak around the diff cover could just be a bad gasket, which is an easy fix.

However, any loss of fluid is serious. Running an axle with low oil will cause the gears to overheat and destroy themselves in short order. If you notice leaking fluids, get it inspected and repaired immediately to avoid a much more expensive future repair.

Your tires can tell you a lot about the health of your suspension and axles. If you notice unusual tire wear patterns, especially on the rear tires, it could be linked to an axle problem. A bent axle housing or a worn-out wheel bearing can cause the wheel to wobble or sit at an incorrect angle, leading to rapid and uneven wear.

For example, excessive wear on the inner or outer edge of a tire can indicate that the axle housing is bent, forcing the tire to ride at an angle. This is more common after a significant impact or if you're running very tall tires without a properly reinforced axle.

Even using an axle of the wrong width can cause alignment issues and premature tire wear. While this is more of a concern with swapped axles, it highlights how critical proper axle geometry is. If your smaller tires are wearing out strangely, have a trusted mechanic check your rear axle for straightness.

How your Grand Cherokee behaves during turns or on the trail can also signal axle issues. If you hear a clunking or binding sound when making tight turns, it could be a sign that the gears inside your differential are damaged or failing. This is especially true for limited-slip or locking differentials.

During off-road adventures, a weak or damaged axle may make itself known through loud popping sounds or a sudden loss of traction to one wheel. A bent axle shaft can cause a noticeable wobble or hop at low speeds. These symptoms will be magnified during extreme trail use when the axles are under maximum stress.

Even high-performance models like the Grand Cherokee SRT aren't immune. Launching a powerful vehicle puts immense strain on the axle shafts, and any weakness will quickly become apparent. If you feel the rear end acting strangely under power, it’s time for an inspection.

Replacing an axle can be a significant investment, so it's good to know what to expect. The total cost depends on several factors, including the price of the parts and the labor charges from your mechanic. A simple axle shaft replacement will be much cheaper than swapping out the entire rear axle assembly.

The average parts pricing can range from a couple of hundred dollars for a single shaft to several thousand for a complete, upgraded axle assembly. The main weak point of a budget is often unexpected labor charges, so it helps to understand the process. Let’s break down the costs involved.

The final bill for a rear axle replacement is influenced by a few key variables. The model year of your Grand Cherokee is a big one, as parts for newer vehicles can be more expensive and the labor more complex. An older ZJ with a simple solid axle will be cheaper to work on than a newer WK2 with more integrated electronic systems.

The choice between OEM and aftermarket parts will also heavily impact the parts pricing. OEM parts from a dealer are typically more expensive than aftermarket alternatives. However, a high-performance aftermarket axle assembly designed for heavy use will cost significantly more than a standard replacement.

Finally, labor charges vary widely by region and the specific shop you choose. A dealership will almost always charge more per hour than an independent mechanic. The complexity of the job—whether it's just an axle shaft or the entire housing—will also determine the total hours billed.

Labor costs for axle replacement and maintenance can vary significantly across the United States, influenced by numerous factors including location, labor market conditions, and the complexity of the task. For instance, urban areas usually present higher rates due to increased demand for skilled technicians who understand the nuances of Jeep Grand Cherokee axles and related components. Offshore and remote locations may offer more competitive pricing, though access to knowledge and expertise could be limited.

Typical charges for axle services range from $100 to $150 per hour, depending on the shop's reputation and the nuances of the service provided. This investment can enhance your Jeep’s performance, especially if you're considering upgrades for extreme trail use or incorporating special features like the vacuum disconnect. Ensure you consult with experienced mechanics to guarantee optimal service.

When it comes to parts, you have a wide range of options and price points. The average parts pricing for a single replacement rear axle shaft is typically between $150 and $400, depending on the brand and your specific Jeep model. This is a common repair for a shaft that has broken or bent.

If you need to replace the entire rear axle assembly, the cost rises dramatically. A used axle from a salvage yard might cost $500 to $1,500, but its condition is always a gamble. A remanufactured OEM axle assembly will be more reliable and could cost between $1,500 and $2,500.

For those looking to upgrade, a new, heavy-duty aftermarket axle assembly from a brand like Currie can start around $4,000 and go up from there depending on options like lockers and gear ratios. While expensive, these offer a massive leap in strength and durability.

The time required for an axle replacement job directly impacts your final labor charges. A skilled mechanic can typically replace a single, easily accessible axle shaft in about one to two hours. This involves removing the wheel and brake assembly, pulling the old shaft, and installing the new one.

Replacing the entire axle housing is a much more involved process. The mechanic needs to safely lift and support the vehicle, disconnect the driveshaft, shock absorbers, and all suspension links, detach the brake lines, and then remove the old assembly. Installing the new one is the reverse of this process and requires careful alignment.

For a full axle assembly swap, you should expect the job to take between four and eight hours. More complex jobs, especially on newer models with intricate suspension setups or if rust is a factor, can take even longer. Always ask for a time estimate upfront.

Feeling adventurous? Replacing an axle shaft or even the entire assembly on your Jeep Grand Cherokee can be a rewarding DIY project if you have the right tools and mechanical experience. A safe installation is the top priority, as mistakes can lead to serious safety issues on the road.

This is not a job for beginners, as it requires heavy lifting and a good understanding of your vehicle's suspension and drivetrain. However, with careful preparation and attention to detail, you can save a significant amount on labor costs. The following sections will guide you through what you'll need.

A comprehensive toolkit is essential for any DIY enthusiast planning to service or replace axles on a Jeep Grand Cherokee. Begin with basic hand tools, including socket sets, wrenches, and pliers, to access various components efficiently. A high-quality jack and jack stands are crucial for safely elevating the vehicle, especially given the weight and size of modern Jeep vehicles.

For more complex tasks, an impact wrench can significantly expedite the removal of stubborn bolts and nuts. Additionally, ensure you have a torque wrench for proper reassembly, maintaining the correct specifications to prevent issues like uneven tire wear. Having a differential cover gasket and suitable axle lubricants on hand is also wise. These supplies will equip you for both routine maintenance and more intensive upgrades to enhance performance during extreme trail use.

Removing an axle from a Jeep Grand Cherokee requires careful attention to detail to ensure a successful process. Start by safely lifting the vehicle and securing it on jack stands to prevent any accidents. Next, disconnect the battery to eliminate any electrical hazards and remove the wheel and brake assembly to gain access to the axle. This involves unbolting the caliper and rotor, followed by the axle nut.

Once the brake components are off, disconnect the differential cover to access the internal components. Removing the axle shaft involves unbolting it from the differential and sliding it out of the axle tube. Ensure that any retaining clips are also removed. Finally, inspect the axle for wear, which can lead to failures in extreme conditions, ensuring your Jeep's performance during off-road adventures.

A safe installation is all about being methodical and torquing every bolt to factory specifications. Rushing this process is the main weak point of any DIY job. Start by carefully moving the new axle assembly under the Jeep and raising it into position with a floor jack.

Attach the suspension components first, but don't fully tighten the bolts yet. This allows you to align everything properly. Once all the control arms and the track bar are connected, you can attach the shocks and driveshaft.

Follow these key steps for a secure installation:

Overlooking the importance of axle specifications can lead to compatibility issues. Selecting the wrong width or spline count may compromise performance and safety, especially when pairing with aftermarket enhancements. Failing to consider the demands of extreme trail use can also result in premature wear, particularly with weaker components like the axle shafts and pinion gears.

Neglecting proper maintenance, such as regular inspections of the differential cover and parking brake, is another common misstep. This can exacerbate issues like vacuum disconnect failures. Prioritizing quality over cost is essential too, since opting for lower-grade parts might lead to greater long-term expenses from repairs. Avoiding these pitfalls not only ensures better fuel economy but also enhances the longevity and reliability of your Jeep Grand Cherokee.

Ready to take your Grand Cherokee to the next level? The aftermarket offers a huge range of performance upgrades for your axles. Swapping in a stout axle assembly is a very good upgrade for anyone serious about off-roading or increasing their vehicle's durability. These upgrades can handle more stress, larger tires, and tougher trails.

Beyond complete assemblies, you can also upgrade individual components like axle shafts, install limited slip differentials for better traction, and choose different gear ratios to optimize performance. These changes can dramatically improve your Jeep's capability and even its towing capacity.

In the realm of Jeep Grand Cherokee modifications, aftermarket axles play a crucial role in elevating performance and durability. Brands like Dynatrac and Currie Enterprises offer robust solutions that cater to serious off-road enthusiasts. Their stout axles enhance ground clearance while supporting larger tires, crucial for extreme trail use. The versatility of these axles is evident in applications ranging from racing to everyday driving.

Brands like ARB and Yukon Gear & Axle also provide excellent aftermarket support, ensuring compatibility with various Grand Cherokee models. With options that address common weak points, such as spline shafts and pinion failures, these products are designed for longevity and reliability, making them the go-to choice for those looking to optimize their Jeep's performance.

If you're planning on extreme trail use, the stock axles under your Grand Cherokee will eventually become your weakest link. Upgrading to a stout axle is essential for reliability when you're miles from civilization. A heavy-duty (HD) axle is built with thicker axle tubes, stronger axle shafts, and a more robust differential housing.

An HD axle can withstand the immense torsional forces generated by large, aggressive tires fighting for traction on rocks and in mud. This upgrade gives you the confidence to tackle difficult obstacles without the constant fear of breaking a shaft or bending a housing.

Many aftermarket HD axle assemblies also offer improved ground clearance and are designed to correct suspension geometry on lifted vehicles. This not only enhances durability but also improves your vehicle's overall off-road performance, making it a worthwhile investment for any serious enthusiast.

Upgrading your differential is one of the best ways to improve traction. Most stock vehicles come with an "open" differential, which sends power to the wheel with the least traction. This is why you might see one tire spinning uselessly in the air while the other sits still. Limited slip differentials (LSDs) solve this problem.

An LSD automatically directs more power to the wheel that has more grip. This provides a significant traction advantage in slippery conditions like snow, mud, or on uneven trails, without the harsh handling characteristics of a full mechanical locker on the street.

While they don't directly impact better fuel economy, limited slip differentials can make your rear axle much more effective, improving all-weather safety and off-road capability. It's a balanced upgrade that offers benefits both on and off the pavement.

Upgrading your axles can have a positive effect on your Grand Cherokee's towing capacity and on-road handling. A stronger axle assembly is better equipped to handle the immense weight and stress that towing places on the rear of the vehicle. The stock axle can be a main weak point when pulling a heavy trailer.

By upgrading to one of the largest axles available for your platform, you increase your margin of safety and reduce the risk of axle failure. Furthermore, changing your gear ratio as part of an axle upgrade can make towing feel effortless, as the engine can operate more efficiently in its powerband.

On-road handling can also improve. A stout axle with a limited slip differential will provide more stable and predictable power delivery, especially when accelerating out of corners. This creates a more controlled and confident driving experience, proving that axle upgrades aren't just for off-roaders.

When it's time to buy a new axle, you have several options. You can choose between OEM (Original Equipment Manufacturer) parts or a wide variety of aftermarket solutions. Your choice will depend on your budget, performance needs, and how quickly you need the part.

You can source these parts from local dealerships, dedicated off-road specialty shops, or a vast number of online axle sellers. Each source has its pros and cons, from the expert advice at a specialty shop to the convenience and selection of online retailers. Let's explore these options further.

Navigating the options between OEM and aftermarket suppliers for your Jeep Grand Cherokee axles can significantly affect your vehicle's performance and longevity. OEM parts are designed specifically for your model year, ensuring a precise fit and reliable functionality, which is essential for maintaining the integrity of the axle system, especially considering their main weak points. However, aftermarket suppliers often provide great aftermarket support, offering parts that may improve performance beyond stock specifications. This can be particularly advantageous for those involved in racing applications or extreme trail use, where enhanced durability and strength are crucial.

With numerous aftermarket options available, it is vital to conduct thorough research to identify components that best fit your vehicle’s needs. Proper selection can lead to better fuel economy and improved handling, maximizing your Jeep's capabilities on various terrains.

Shopping with online axle sellers can be incredibly convenient, offering a massive selection and competitive prices right at your fingertips. However, it's crucial to do your homework to ensure you get the right part for your front axle or rear axle.

Before you click "buy," make sure you have correctly identified your current axle. Have your Jeep's year, make, model, and axle type ready. Reputable online stores will have detailed product descriptions and vehicle fitment guides to help you confirm you're ordering the correct component.

Follow these tips for a smooth online purchase:

While online shopping is popular, don't overlook the value of local dealerships and specialty shops. Your Jeep dealership's parts department is the most reliable source for OEM parts. The staff can use your VIN to guarantee you get the exact rear axle component you need, eliminating any guesswork.

Understanding Jeep Grand Cherokee axles often raises questions among enthusiasts. Common queries include the differences between front and rear axles, as well as compatibility with taller tires. Many owners of the Jeep Grand Cherokee WK and others often wonder if upgrading to larger spline axles offers better performance during extreme trail use. Concerns about the common weak points, like pinion failures and venerating weak axle tubes, are also prevalent. For those considering modifications, understanding the necessary lengths and widths of axle shafts ensures optimal fitment, providing peace of mind on your off-road adventures.

Absolutely! Upgrading to stronger axles with thicker axle tubes is a very good upgrade for any Grand Cherokee intended for extreme trail use. It's one of the best ways to improve durability and reliability, allowing you to run larger tires and tackle tougher off-road obstacles with greater confidence.

Standard axles are solid housings typically found on older Grand Cherokee models. Newer models with independent front suspension use CV axles, which have flexible joints to allow the wheels to steer and move up and down. While offering a better on-road ride, the CV joints can be a main weak point during aggressive off-roading.

Replacing an axle shaft can be a manageable DIY project for someone with mechanical experience. However, swapping the entire axle assembly is a difficult and heavy job that requires specialized tools and a high focus on safe installation. For most people, this job is best left to a professional mechanic.

The best axle for your Jeep Grand Cherokee depends on your budget and how you use it. For daily driving, a stock replacement rear axle is fine. For serious off-roading, an aftermarket Dana 44 or 60 is ideal. Proper axle identification based on your model year is the first step.

In summary, understanding the axles of your Jeep Grand Cherokee is essential for maintaining optimal performance and ensuring a smooth driving experience. From recognizing the signs that indicate your axle may need replacement to exploring aftermarket upgrades that can enhance your vehicle's off-road capabilities, knowledge is power. Whether you're considering a DIY installation or seeking professional help, being informed about the specific needs of your Grand Cherokee will help you make the best decisions for your vehicle. Embrace the journey of Jeep ownership with confidence, knowing you are equipped to handle any axle-related challenges that come your way. If you’re ready to dive deeper into axle solutions, don't hesitate to reach out for expert advice or assistance!

https://www.youtube.com/@OverlandingOzarks

https://www.youtube.com/watch

https://www.carscoops.com/2020/10/mexicos-2020-jeep-grand-cherokee-armored-can-help-you-survive-the-bad-guys/

https://web.archive.org/web/20200803181435/http://www.media.fcaemea.com/it-it/fiat/press

https://web.archive.org/web/20110810185225/http://www.jeep.de/grand_cherokee/modelle/laredo_30_crd/index.html

https://web.archive.org/web/20090204113755/http://news.prnewswire.com/DisplayReleaseContent.aspx

https://web.archive.org/web/20160807045805/http://www.jeeppress-europe.com/press/article/117467

https://web.archive.org/web/20200809023859/http://media.chrysler.com/newsrelease.do;jsessionid=B73078F482035275120A766458134B3D

https://web.archive.org/web/20120110023127/http://www.allpar.com/news/index.php/2012/01/chrysler-sales-shoot-up-37-26-for-2011

https://web.archive.org/web/20090605064220/http://www.prnewswire.com/cgi-bin/stories.pl

https://web.archive.org/web/20090203224451/https://www.reuters.com/article/pressRelease/idUS217066%2B03-Jan-2008%2BPRN20080103

https://www.ancap.com.au/safety-ratings/9fafab

https://www.ancap.com.au/safety-ratings/c98bbf