RENEGADE vs OUTLAW AXLES

Renegade vs Outlaw

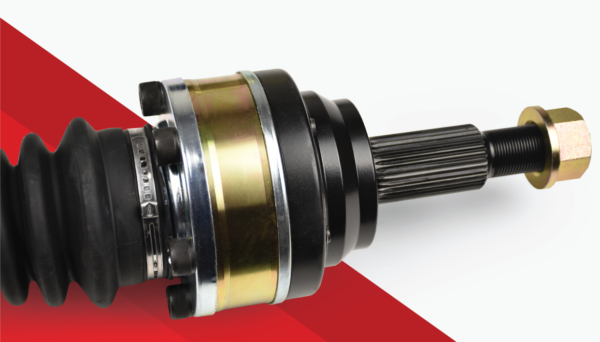

The GForce Renegade Axles are the tried and true axle design that has become the standard in performance half-shafts. The Renegade axle has waivered very little from its roots some 15 years ago. Advancements in materials, heat-treat processes and machining have only improved their efficiency and capabilities. It is hard to argue with the Renegade’s pedigree for strength and overall value.

The GForce Outlaw Axles were introduced as the next iteration in the GForce line-up, boasting unparalleled performance and durability even in the most extreme driving environments. The Outlaw axles use a unique and uniform surface treatment that helps cut down on rolling resistance and wear. This is helpful in just about every application as CV’s will almost always be functioning at some angle. Additionally, the CV ball bearings are constantly traveling back and forth in the CV housing every rotation of the axle. That equates to a lot of work and, in turn a lot of heat production. Ultimately, the Outlaw CV is more efficient, which means more energy from the engine to the tires with less effort. As a byproduct, we see less heat because of the decreased rolling resistance and this translates to longer CV life.

Heat and friction will gradually break down CV grease until it no longer functions as a lubricant. The Outlaw axles also get a top-of-the-line grease, which has a higher heat flash point and superior lubrication qualities in comparison to what is used in the Renegade axles.

The CV to stub joint is a critical mating point that relies solely on clamping force to hold the stub in place relative to the CV and axle bar. The Renegade axles get a standard 12.9 socket headed cap screw, where the Outlaw axles get a 12-point ARP fastener to help with overall strength and clamping force.

The GForce Outlaw Axles were introduced as the next iteration in the GForce line-up, boasting unparalleled performance and durability even in the most extreme driving environments. The Outlaw axles use a unique and uniform surface treatment that helps cut down on rolling resistance and wear. This is helpful in just about every application as CV’s will almost always be functioning at some angle. Additionally, the CV ball bearings are constantly traveling back and forth in the CV housing every rotation of the axle. That equates to a lot of work and, in turn a lot of heat production. Ultimately, the Outlaw CV is more efficient, which means more energy from the engine to the tires with less effort. As a byproduct, we see less heat because of the decreased rolling resistance and this translates to longer CV life.